- What is Digital Transformation Consulting?

- Why SMBs and Startups Need Specialized Digital Consulting Partners

- What do SMBs need instead?

- Top 10 Digital Transformation Consulting Companies (2026)

- Runner-Ups & Niche Standouts Worth Watching

- Comparison Table: Top 30 Digital Transformation Consulting Companies

- How to Choose the Right Digital Transformation Consulting Partner

- SMBs vs. Enterprises: Different Needs, Different Partners

- Why Gart Solutions is One of the Leaders

- The Future of Digital Transformation Consulting (2026–2030)

- Conclusion: Choose Smart, Transform Faster

In a market driven by change, speed, and automation, small and mid-sized businesses (SMBs) can no longer rely on legacy systems or gut decisions. Digital transformation becomes a necessity. Whether you’re scaling a tech startup, modernizing operations, or simply trying to compete with digital-first rivals, one thing is clear: transformation is mandatory.

But here’s the tricky part — most digital transformation frameworks were built for enterprises, not the lean, fast-moving, budget-conscious world of SMBs. That’s where specialized consulting firms come in. They help you not just adopt new tech, but align it with your strategy, optimize operations, and unlock real business value.

In this guide, we’ll walk you through the best digital transformation consulting companies, especially those with a track record of helping SMBs and fast-growing companies achieve real ROI. We’ll start with our top 10 picks and wrap up with a table of 30 top-rated global providers.

What is Digital Transformation Consulting?

Let’s clear up the confusion — digital transformation isn’t just about “going paperless” or “moving to the cloud.” It’s not just building an app or revamping your website. True digital transformation is a fundamental rethinking of how your business operates, interacts with customers, delivers value, and competes in a fast-changing world.

A digital transformation consulting firm helps you plan, design, and execute this journey. Their role is not just technical — it’s strategic, operational, and cultural. They help you answer the big questions:

- What does digital success look like for your business?

- Where is your tech stack holding you back?

- Which processes can be automated or optimized?

- How do you adopt AI, cloud, or analytics without disrupting everything?

A great consulting partner will work with your team to:

- Assess your digital maturity: What systems are outdated? What tools are siloed? Where’s the bottleneck?

- Design a digital roadmap: This isn’t just about shiny tech. It’s about aligning transformation with your business model and goals.

- Select and implement technology: From cloud platforms (like AWS, Azure, or GCP) to automation tools and custom software, they guide tech decisions that scale with your growth.

- Modernize legacy systems: You don’t always need to scrap your entire stack — sometimes, smart modernization is the move.

- Introduce data and analytics: So you’re not guessing, you’re making decisions backed by insights.

- Support organizational change: Transformation isn’t just tech — it’s about people, mindset, and process.

Let’s clear this up: digital transformation isn’t just “getting on the cloud” or building an app. It’s a complete rethinking of how your business uses technology — from internal operations to customer interactions. Digital transformation consulting companies help businesses define that vision, build a roadmap, implement the right tech, and navigate the human side of change.

What does a digital transformation consultant actually do?

- Audits current digital maturity

- Builds a strategy and transformation roadmap

- Guides cloud migration or hybrid architecture design

- Optimizes DevOps, CI/CD, and IT processes

- Modernizes legacy systems and workflows

- Enhances customer experience via digital platforms

- Introduces analytics, automation, and AI tools

And it’s not just about tech. In short, digital transformation consultants bridge the gap between vision and execution. They bring technical expertise, strategic clarity, and operational muscle — especially valuable for SMBs who don’t have internal innovation teams or massive IT departments.

Why SMBs and Startups Need Specialized Digital Consulting Partners

Let’s be honest — most small and mid-sized businesses don’t have millions to throw at consultants or 12 months to “wait and see results.” The average SMB needs ROI yesterday. That’s why traditional enterprise consultancies often miss the mark for this segment.

So, why can’t SMBs just go with a big-name firm?

- They’re slow: Multi-year rollouts don’t work when you’re trying to survive Q2.

- They’re expensive: SMBs can’t afford $500/hour consulting rates or multi-phase discovery projects with no deliverables.

- They overbuild: Enterprise strategies often involve over-engineered solutions — when lean, agile options would do the trick.

- They don’t speak SMB: Big firms often don’t understand the urgency, culture, or pace of smaller teams.

What do SMBs need instead?

✅ Quick Wins

Small changes that drive immediate value. That could be automating a workflow, reducing cloud costs, or launching a new customer-facing app. Consultants who specialize in SMBs focus on momentum, not just planning.

✅ Agility and Flexibility

You need a partner who can pivot with you, scale services as you grow, and roll with your evolving priorities. SMB consultants embrace change — they don’t fear it.

✅ Right-Sized Budgets

You want outcomes, not bloated project plans. The best consulting partners focus on ROI-first strategies, using open-source tools, efficient architectures, and creative solutions to stay lean.

✅ Strategic + Technical Expertise

You don’t just need someone to “install software.” You need someone who understands your business model, challenges, and growth goals — and builds tech to match.

✅ Long-Term Scalability

The tech you implement today should still serve you tomorrow. Smart consultants build systems and strategies that evolve as your company scales.

Bottom line? SMBs need partners — not vendors. The best digital transformation consulting firms for this market don’t just drop in and leave. They work with you, understand your goals, and evolve alongside your team.

Top 10 Digital Transformation Consulting Companies (2026)

1. Gart Solutions – Infrastructure-Led Transformation for SMBs

When it comes to SMB-friendly digital transformation, Gart Solutions sets the gold standard. This firm is all about practical, measurable transformation for SMBs and scaling companies. Unlike larger consulting giants, Gart doesn’t just hand you a 50-slide deck — they build, implement, and optimize.

If you’re an SMB or scale-up looking for a consulting partner that’s fast, focused, and doesn’t waste time— Gart Solutions should be at the top of your list. This boutique firm has quietly become the gold standard for cloud-native transformation and DevOps excellence.

What sets Gart apart isn’t just technical expertise — though they have plenty. It’s their “Quick Wins” methodology. While other firms are still hosting kickoff meetings, Gart is already optimizing your CI/CD pipeline or cutting your cloud costs. For budget-conscious SMBs that need real outcomes fast, this is a game-changer.

Their services cover:

- CloudOps and multi-cloud architecture (AWS, Azure, GCP, Hetzner)

- DevOps managed services

- Infrastructure as Code (Terraform, Kubernetes)

- Application modernization

- Data and analytics enablement

One of their most impressive case studies? Helping a Thai jewelry manufacturer reduce cloud spend by 81% by replacing legacy video processing workflows with Azure Spot VMs and automated pipelines. Another? Building a disaster recovery setup for ESG platform Datamaran that cut downtime from days to minutes, ensuring 99.99% uptime.

They also specialize in turning technical debt into scalable infrastructure. Rather than ripping everything out, they help modernize legacy systems to meet today’s demands — affordably and fast.

Gart’s pricing is SMB-friendly ($50–$99/hr), but their delivery rivals firms 10x more expensive. With a senior team of fewer than 50 engineers, they offer high-touch, personalized service. You won’t get bounced between project managers — you’ll work directly with experts who understand your stack, your product, and your pressure to move fast.

Best for: SMBs, tech startups, or fast-growing scale-ups looking for agile, cloud-first infrastructure transformation without enterprise bloat.

2. Enfuse Group: Behavioral-Driven Digital Change

Let’s be real — not all transformation challenges are about tech. In fact, 60% of digital transformation projects fail due to people and culture issues, not the software. That’s why Enfuse Group, based in London, is one of the most unique and valuable consulting firms on this list.

Their core philosophy? “Digital transformation is a behavioral problem, not just a technical one.” This mindset drives everything they do.

Enfuse helps SMBs and mid-market firms redesign their operating models, employee experiences, and decision-making workflows — all through a lens of behavioral science. Their “BeHuman” methodology is a structured approach to change management, aligning teams, leadership, and tech adoption strategies.

They focus on:

- Culture transformation and change readiness

- People tech (HR systems, talent platforms)

- Operating model redesign

- Scalable AI-enabled process design

- Employee experience optimization

Their work spans retail, hospitality, education, and logistics — sectors where frontline employees are often the missing link in failed tech projects. Post-2025, Enfuse has doubled down on employee-focused transformation after receiving investment from Agathos Capital. That means better tools, better support, and better ROI from every tech investment.

If your company struggles with “people bottlenecks” — poor communication, slow adoption, or digital fatigue — Enfuse offers a powerful, often overlooked path to progress.

Best for: SMBs with people-heavy operations (retail, logistics, education) that need cultural alignment and operating model redesign alongside tech modernization.

3. Artkai

When your product is complex, your industry is regulated, and your users expect Netflix-level experience — Artkai is the partner you call.

This Ukraine- and Poland-based firm leads with design and user experience, but don’t confuse that with “just UI.” Artkai blends product discovery, strategic consulting, and high-end engineering to deliver enterprise-grade digital platforms. What’s more impressive? They do it in sectors like fintech and healthtech, where compliance isn’t optional — it’s life-or-death.

Their specialty is working with companies that:

- Have legacy platforms that need modernization

- Operate in highly regulated environments (HIPAA, GDPR, PCI-DSS)

- Want to align digital products with business strategy

- Need platforms that scale without sacrificing UX

Artkai takes clients through a full-cycle transformation: from product ideation to scalable cloud architecture. And they do it with one goal — to future-proof your core platform while delivering a sleek, intuitive experience.

They’re not the cheapest option on this list, but the investment pays off when you consider that most SaaS churn is caused by poor UX or unclear value. Artkai helps you fix both.

Best for: Fintech, healthtech, or SaaS companies that need to modernize legacy products and deliver consumer-grade digital experiences.

4. Argano: AI-Driven Tech Stack for Growth

If your SMB is scaling fast and your current systems feel like they’re always playing catch-up, Argano might be your ideal transformation partner. Headquartered in Plano, Texas, Argano is a U.S.-based consultancy that has become known for its AI-forward, platform-agnostic approach to enterprise technology — and yes, they’re just as effective for mid-market companies.

What makes Argano stand out is their focus on designing and delivering connected business operations. This includes everything from ERP modernization to data intelligence, CRM upgrades, and embedded AI — all without forcing clients into one specific vendor ecosystem. Whether you’re running on Microsoft, Oracle, SAP, or a combination, Argano’s integration-first model makes it all work together.

Here’s what they specialize in:

- ERP transformation and modernization

- CRM and customer journey orchestration

- AI-powered decision intelligence

- Digital strategy alignment

- Scalable cloud-native solutions

What SMBs love most is their “hands-on” model — the same experts stay with your project from start to finish. No bouncing between teams. This consistency leads to faster decisions, fewer surprises, and higher accountability — something larger firms often fail at.

Their deep industry focus spans healthcare, manufacturing, financial services, and retail — all spaces where operational complexity and compliance demand both tech sophistication and a practical delivery model.

And here’s a bonus: Argano’s combined legacy of multiple boutique firms means they’ve got over 100+ years of consulting depth, rolled into one modern delivery team.

Best for: Mid-market companies looking for full-stack transformation across ERP, CRM, and AI — without being locked into one tech provider.

5. Yalantis: IoT and Full Product Lifecycle Expertise

Need a consulting partner that goes beyond software — into hardware, IoT, and edge computing? Yalantis, based in Ukraine, is one of the few boutique consultancies that can handle the entire digital product lifecycle, from prototyping to scalable deployment.

Yalantis is built for businesses that straddle the digital-physical line: logistics platforms, health tech startups, manufacturing systems, and smart device innovators. In a world where sensors, mobile apps, cloud platforms, and APIs must work in harmony — they make it happen.

What makes Yalantis special?

- Deep expertise in IoT architecture

- Microservices-based software design

- Real-time analytics and monitoring tools

- Remote device control platforms

- UX-first design for hardware-integrated software

They’ve grown rapidly, with a 54% annual growth rate, and now boast over 500 professionals delivering high-velocity engineering for global clients. Their client results include massive improvements in order processing speed, failed transaction reduction, and remote device management.

Yalantis doesn’t just build — they co-create. That means working alongside your team, defining product specs, refining UX, and ensuring regulatory compliance. For SMBs trying to create something complex without hiring a massive in-house dev team, this kind of hybrid expertise is invaluable.

Best for: Logistics, healthcare, and manufacturing SMBs building connected digital-physical systems, or launching smart products with IoT integration.

6. Sombra Inc: Hybrid AI Integration & Cloud Execution

Need to modernize both your infrastructure and integrate AI — without breaking the bank or derailing your operations? Sombra Inc offers one of the best hybrid transformation models on the market.

Founded in Ukraine and now operating globally (including North America), Sombra specializes in helping SMBs choose the right path between buying, building, or blending AI tools. Their 2026 “AI Playbook” outlines detailed cost comparisons — from SaaS models to full custom solutions — giving companies a transparent path to ROI.

Sombra’s services include:

- Cloud architecture and migration

- AI integration and API blending

- Custom product development

- Data warehousing and analytics

- DevOps optimization

Where they really shine is in building “production-ready mini-stacks” — lightweight, scalable software systems complete with private endpoints, audit logs, and real-time data streaming. These solutions help clients deploy AI in live environments with minimal disruption and maximum value.

Their hybrid cloud and AI expertise is especially helpful for:

- Fintech and healthtech startups

- Logistics and operationally complex SMBs

- Companies migrating from legacy tools to modern stacks

Sombra works lean, fast, and flexibly — a rare combo in the consulting world. And because they specialize in SMBs, they respect budgets, timelines, and internal resource limits.

Best for: SMBs seeking to blend AI with cloud modernization, and need a clear, affordable path to scale without overbuilding.

7. S-PRO: Fintech and Renewable Tech Specialists

For companies operating at the intersection of finance and innovation — especially in fintech, crypto, or renewables — S-PRO is a standout. Based in Ukraine with strong Swiss partnerships, S-PRO has carved out a niche building modern, scalable, and compliant platforms for some of the most regulated, fast-moving industries.

Key service areas include:

- Fintech software development

- DeFi and blockchain integration

- ESG and sustainability tech

- Wealth management solutions

- Custom banking platform modernization

Their deep knowledge of the Swiss banking system, plus hands-on experience with crypto exchanges and next-gen payment infrastructure, gives them an edge few firms can match. They’ve helped clients like Hyposwiss and Amina Bank launch new products that comply with both traditional finance laws and emerging crypto regulations.

What SMBs love about S-PRO is their agile team structure. They don’t overstaff. Instead, they bring in the exact right mix of architects, developers, and strategists, build fast, and stay transparent.

If you’re in fintech or ESG-driven spaces and need a transformation partner that gets both the tech and regulatory landscape, S-PRO delivers.

Best for: Fintech startups, wealth platforms, crypto firms, and ESG-focused SMBs needing secure, scalable product development and transformation.

Runner-Ups & Niche Standouts Worth Watching

While the top 10 firms dominate across multiple SMB use cases, several high-performing runner-ups stand out for their specialization, innovation, or regional excellence. These companies may not be one-size-fits-all, but in the right context, they’re absolute game-changers.

Glorium Technologies

Headquartered in the US with R&D centers in Ukraine, Glorium focuses on healthtech, proptech, and custom platform development. They’re ideal for SMBs building digital products that need rapid scaling, HIPAA compliance, and seamless user experience. Glorium brings strong automation and MVP-launch capabilities, making them a solid choice for early-stage startups and post-seed companies looking to mature their tech stack without overbuilding.

Railsware

Railsware has a cult-like following among product-led startups, and for good reason. Known for its engineering-first culture and for building products like Calendly and BrightBytes, Railsware approaches transformation from a product strategy + analytics perspective. Their strength lies in helping SaaS firms and product-centric SMBs make better build-or-buy decisions and optimize internal tooling.

SoftServe

One of the giants in the Ukrainian ecosystem, SoftServe brings massive scale to AI, machine learning, cloud, and data engineering. While they mostly serve enterprise clients, SoftServe has flexible engagement models for high-growth SMBs and innovation teams inside larger firms. If your goals involve enterprise-grade AI, SoftServe delivers.

Xmethod

This Berlin-based firm is a rising star in the healthcare transformation scene, building MVPs using low-code/no-code tools. If you’re a digital health startup or SMB looking for rapid prototyping, telemedicine deployment, or compliance-ready patient engagement platforms — Xmethod is fast, affordable, and effective.

Softermii

Softermii is a Ukraine-based firm making waves in video-tech and healthcare. With proprietary tools like VidRTC, they’re helping healthcare and event platforms build scalable, real-time digital experiences. Their dedicated team model is perfect for SMBs that need a dev squad embedded into their workflow.

Comparison Table: Top 30 Digital Transformation Consulting Companies

| Company Name | Key Strengths | Best For |

|---|---|---|

| Gart Solutions | Cloud, DevOps, strategy, SMB-focused | Small and mid-size tech firms, tech startups and scaleups |

| Hexagon Agency | Strategy, marketing, UX | Small businesses |

| Glorium Technologies | Custom platforms, automation | Growth-stage startups |

| Strategic Consulting UA | Change readiness, frameworks | Organizational alignment |

| N-iX | AI, data, cloud | Cross-industry transformation |

| Sombra Inc. | DevOps, modernization | Infrastructure transformation |

| Railsware | Product strategy, analytics | SaaS, product-led teams |

| Eleks | Enterprise automation | Enterprise-level transformation |

| BCG | Strategy + transformation | Funded SMBs, enterprises |

| McKinsey Digital | Design thinking, agile | High-budget initiatives |

| Accenture | Innovation labs, CX | Enterprise consulting |

| EPAM Systems | Agile, CX, engineering | Large tech projects |

| SoftServe | AI, cloud, analytics | Innovative SMBs |

| Avenga | CRM, healthcare | Regulated industries |

| Luxoft | AI, digital finance | Fintech, automotive |

| Sigma Software | AI, AR/VR, engineering | Advanced industries |

| Intellias | IoT, cloud | Mobility and tech projects |

| AltexSoft | Analytics, travel-tech | Niche SMBs |

| DataArt | Fintech, healthcare | Regulated sectors |

| IT Svit | Cloud-native, DevOps | Infrastructure upgrades |

| Innovecs | Gaming, logistics | Vertical-specific needs |

| Softengi | RPA, digital twins | Tech-heavy firms |

| Zazmic | Product dev, growth ops | Startups |

| Yalantis | UX, platforms | Customer-focused design |

| Dev.Pro | Agile teams, scaling | MVP to enterprise growth |

| Timspark | Team extension, consulting | Flexible staffing |

| Ciklum | Engineering, product dev | Digital enterprise growth |

| Andersen | Agile, cloud | Hybrid transformation |

| Digis | DevOps, product blend | Mid-size tech firms |

| Infopulse | Cybersecurity, IT ops | Risk-sensitive orgs |

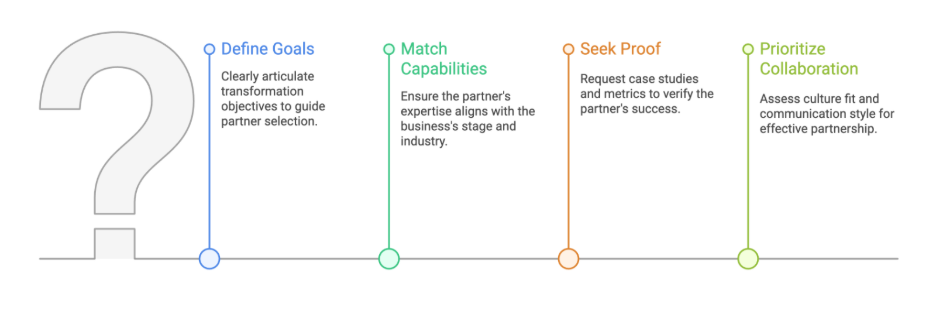

How to Choose the Right Digital Transformation Consulting Partner

1. Define Your Transformation Goals

- Do you need strategy, tech enablement, or both?

- Are you focused on cloud, DevOps, data, or UX?

- Is this a full overhaul or incremental change?

2. Match Scope with Capabilities

- Don’t hire enterprise firms for startup problems

- Look for firms that understand your stage and industry

- Seek right-size expertise

3. Look for Proof, Not Promises

- Ask for case studies and results

- Demand measurable metrics and success stories

- Find partners who deliver outcomes, not just ideas

4. Prioritize Collaboration

- Look for partners, not vendors

- Culture fit and communication style are crucial

- Make sure you’ll work well together under pressure

SMBs vs. Enterprises: Different Needs, Different Partners

| SMBs | Enterprises |

|---|---|

| Lean budgets | Larger investments |

| Need fast ROI | Long-term strategy |

| Flexible partners | Structured processes |

| Require tech + business help | Have internal strategy teams |

SMBs should go for agile, cost-effective firms like Gart Solutions, Hexagon, or Glorium.

Why Gart Solutions is One of the Leaders

Gart Solutions combines strategy, tech, and implementation under one roof — without breaking your budget. They offer:

- End-to-end transformation services

- DevOps, cloud, and legacy modernization

- Data and analytics frameworks

- Custom roadmaps for SMBs

- Affordable rates with enterprise-level results.

Gart is hands-on, strategic, and results-driven — perfect for ambitious SMBs.

The Future of Digital Transformation Consulting (2026–2030)

Digital transformation is no longer a one-time project. It’s a continuous journey, and the next few years will see even more disruptive shifts. Here’s where we’re headed:

1. AI-First Transformation

By 2030, nearly every SMB will need to embed AI into operations — not just for analytics, but for automation, personalization, and predictive decision-making. Consulting firms will shift from “digital advisors” to AI orchestrators — helping you buy, build, and train the right models.

2. Hyperautomation

Expect a rise in process orchestration platforms, where everything from onboarding to logistics can be automated end-to-end using RPA + AI + analytics. The best firms will build cross-functional automation maps, not just isolated tools.

3. Verticalization

Generic consulting is dead. SMBs want industry-specific insight — whether it’s compliance in healthcare, customer journey mapping in fintech, or UX for SaaS onboarding. The top firms will specialize deeply in vertical problems.

4. Remote-First Execution

The best consulting firms will be remote-native, with async workflows, global teams, and 24/7 delivery cycles. This benefits SMBs that need speed without geographical limitations.

5. AI Compliance & Security by Design

As AI regulation grows, expect firms to prioritize explainability, data lineage, audit readiness, and zero-trust security models. Smart SMBs will choose consultants who can make them future-compliant — not just feature-rich.

Conclusion: Choose Smart, Transform Faster

Digital transformation isn’t optional anymore — it’s mission-critical. But for SMBs, success doesn’t come from buzzwords or bloated roadmaps. It comes from finding the right partner — one who speaks your language, understands your pace, and builds tech that actually moves the needle.

Whether you need cloud migration, AI adoption, legacy system upgrades, or full-stack platform development, the firms listed here represent the best of 2026 — boutique powerhouses with the talent, tools, and mindset to help you transform with clarity, confidence, and speed.

Start small. Move smart. Measure everything.

And above all — choose partners who make your growth their mission.

If you’re ready to reduce downtime, boost efficiency, and update legacy systems for the future — Gart Solutions is here to help you make that leap.

Whether you’re an SMB, needing guidance or a growth-stage company scaling your infrastructure, Gart Solutions’ Digital Transformation Consulting is targeting your sustainable growth.