- Understanding Successful Digital Transformation

- The Evolution of Automotive Manufacturing

- Key Drivers of Digital Transformation in Automotive

- Smart Manufacturing in the Automotive Sector

- Use Cases of IoT in Automotive:

- Software-Defined Vehicles (SDVs)

- Partnering for Smart Vehicle Success

- Vehicle-to-Vehicle (V2V) and V2I Communication

- Digital Twin Technology in Automotive Production

- How Gart Solutions Can Help

- AI and Machine Learning in Automotive Factories

- Why DevOps and Data Infrastructure Matter

- Blockchain in Supply Chain Management

- Key Benefits of Blockchain in Automotive Supply Chains:

- How Gart Solutions Supports Blockchain Adoption

- Cloud Computing and Data Management

- Gart Solutions – Your Transformation Partner: Case Studies

- Overcoming Challenges in Digital Transformation

- Lessons from NSG and Gart Solutions

- Future Trends in Automotive Digitalization

- Conclusion

Think back to the days when building a car was all about heavy machinery, long assembly lines, and manual labor. Fast forward to today, and it’s a whole new world. Automotive manufacturing is no longer just about assembling metal parts — it’s about data, automation, software, and intelligence. That shift? It’s all thanks to digital transformation.

Digital transformation is the backbone of modern innovation. In the context of automotive manufacturing, it means using cutting-edge technologies to reinvent how vehicles are designed, built, and delivered. It’s now reshaping the way automakers operate, adapt, and compete in a rapidly changing world.

But digital transformation isn’t just about adding a few robots to the factory floor. It’s about rethinking entire processes, integrating technologies like AI, IoT, and blockchain, and pushing the envelope on what’s possible.

It’s a journey, and the automotive industry is right in the driver’s seat.

Understanding Successful Digital Transformation

So, what does it really mean to successfully transform digitally?

It’s more than just installing new software or automating a few tasks. Success in digital transformation is real results — greater efficiency, higher profitability, and a smoother, more enjoyable experience for customers and employees alike. It’s about becoming future-ready.

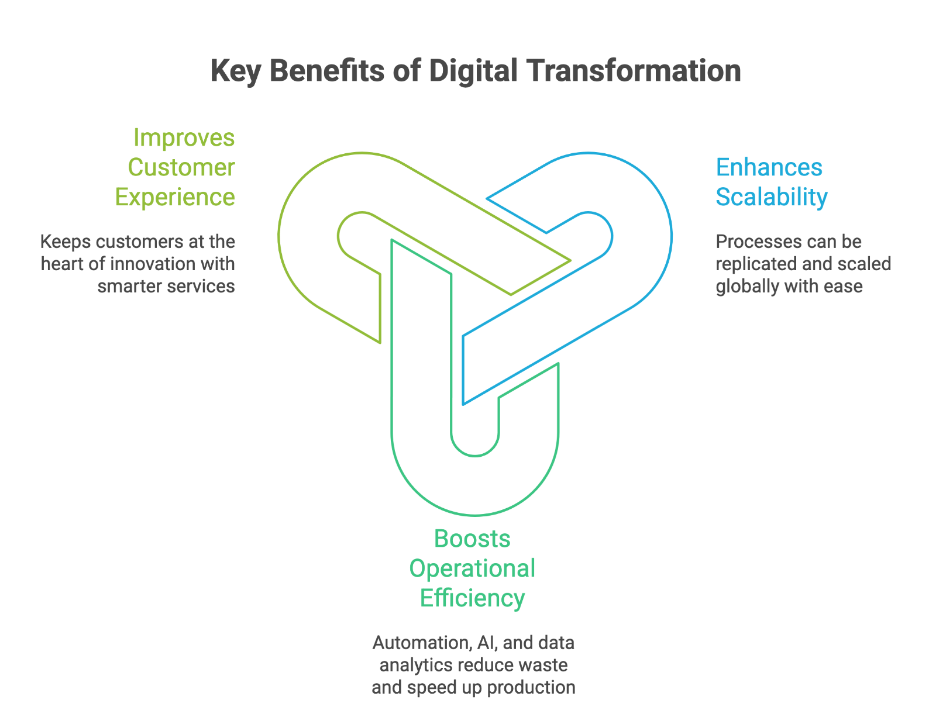

At its core, successful digital transformation:

- Enhances scalability: Processes can be replicated and scaled globally with ease.

- Boosts operational efficiency: Automation, AI, and data analytics reduce waste, speed up production, and lower costs.

- Improves customer experience: From smarter vehicles to seamless post-sale services, it keeps customers at the heart of innovation.

Think of it as a full business evolution. Companies that do it right not only adapt to change— they lead it.

The Evolution of Automotive Manufacturing

Once upon a time, automotive manufacturing was all about mechanical engineering. Steel, gears, welding sparks, conveyor belts — that was the image. But fast forward to today, and the modern automotive factory is part software lab, part cloud control room, and part data command center.

Manufacturing has become digital at its core. What used to be a manual, linear process is now cyber-physical — with embedded sensors, real-time analytics, and automation systems that “think” faster than any human.

Here’s how the landscape has evolved:

- Design is now simulation-led. Engineers use CAD, digital twins, and simulation tools to test everything virtually before it’s built.

- Assembly is automated. Robotics handle welding, painting, and precise assembly with near-zero defects.

- Data flows continuously. Machines talk to each other. Systems auto-correct. Leaders make decisions based on dashboards, not hunches.

This shift is driven not just by tech, but by expectations — customers want smarter cars, regulators demand cleaner factories, and executives need to reduce waste and increase output.

That’s where IT support and infrastructure become critical.

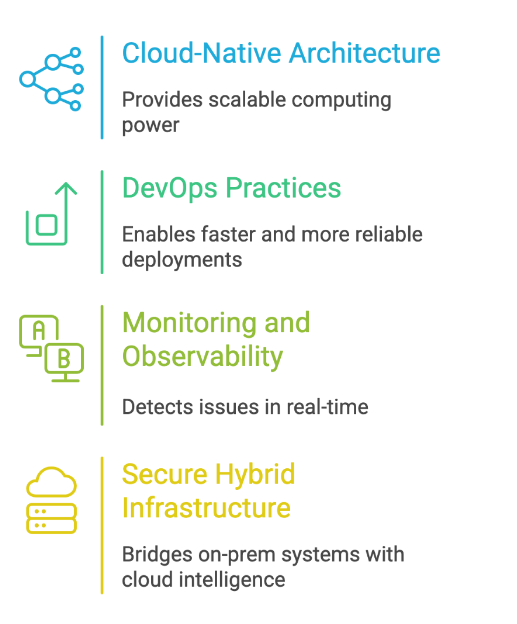

As outlined in Gart Solutions’ guide to IT support for manufacturing, a successful digital transformation requires:

- Cloud-native architecture for scalable computing power.

- DevOps practices deploying changes faster and more reliably.

- Monitoring and observability to detect issues in real-time.

- Secure hybrid infrastructure that bridges on-prem systems with cloud-based intelligence.

Gart Solutions doesn’t just implement tools — they help you build a digital ecosystem that’s resilient, scalable, and secure. As more automakers shift toward software-defined vehicles, having this backbone in place isn’t just important — it’s essential.

Key Drivers of Digital Transformation in Automotive

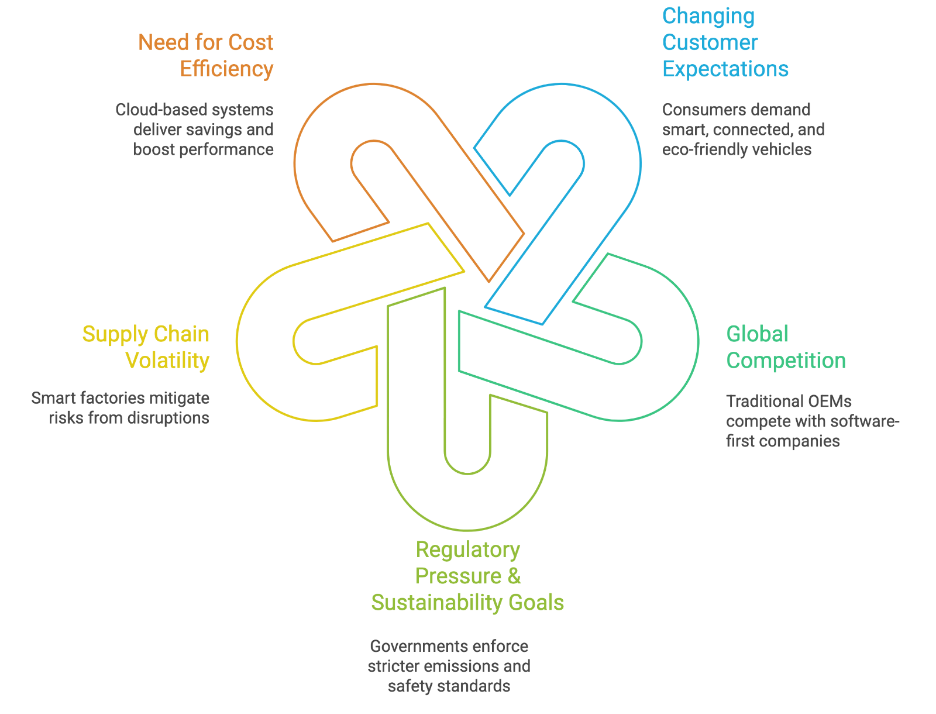

What’s pushing this rapid digital shift across the automotive world? Let’s break it down:

1. Changing Customer Expectations

Consumers now expect more than just horsepower — they want smart, connected, eco-friendly vehicles with custom features, intuitive UIs, and digital experiences that mirror smartphones. That demand requires manufacturers to embed software, sensors, and real-time connectivity into their production process.

2. Global Competition

Tesla’s rise didn’t just shake up the EV space — it redefined the manufacturing playbook. Traditional OEMs now compete with software-first companies. To stay competitive, they must embrace agile production methods, faster development cycles, and automated testing environments — all of which Gart’s cloud and DevOps solutions can accelerate.

3. Regulatory Pressure & Sustainability Goals

Governments worldwide are tightening emissions rules and enforcing stricter safety standards. Digital transformation enables smarter compliance by tracking data across the supply chain — from material sourcing to final inspection.

4. Supply Chain Volatility

COVID-19, geopolitical shifts, and raw material shortages showed how fragile traditional supply chains can be. Smart factories — built on digital visibility, predictive analytics, and real-time dashboards — help mitigate these risks.

5. Need for Cost Efficiency

The margins are thin. Efficiency is everything. Solutions like Azure Spot VMs — used by Gart Solutions to cut AI infrastructure costs by 81% — show how cloud-based systems can deliver serious savings while boosting performance.

Transformation isn’t optional. It’s now the baseline.

Smart Manufacturing in the Automotive Sector

Smart manufacturing isn’t just a catchy term — it’s a blueprint for how modern automotive plants are becoming intelligent, adaptive, and data-driven.

At its core, smart manufacturing leverages technologies like IoT, AI, robotics, machine learning, and cloud computing to create systems that are self-monitoring, self-learning, and self-optimizing.

Let’s break this down into what’s happening on the shop floor:

Real-Time Visibility

With Industrial IoT (IIoT), every machine, sensor, and workstation becomes a data source. Tools like AWS IoT SiteWise or Azure IoT Hub collect data on temperature, vibration, energy use, and production speed — creating a real-time pulse of factory operations.

These insights are then visualized in dashboards that help managers:

- Spot inefficiencies

- Monitor KPIs across shifts

- Adjust line performance before it leads to waste

As highlighted in Gart’s DevOps guide for manufacturers, this kind of real-time observability isn’t optional — it’s mission-critical for companies aiming to scale agile production processes.

Automation with Intelligence

Industrial robots are now smarter than ever. They don’t just perform repetitive tasks — they adjust in real-time based on sensor input and can work safely alongside humans (thanks to collaborative robotics).

Machine learning helps detect patterns, such as:

- Anomalies in parts or assembly

- Predictable failure points

- Areas where energy is being wasted

Companies like Toyota and GM are now deploying self-learning algorithms to fine-tune production and minimize downtime. The result? Higher quality at lower cost.

Scalable Infrastructure

Here’s where cloud infrastructure matters. When your manufacturing ops are driven by data, you need a backend that can scale, integrate, and adapt.

That’s where partners like Gart Solutions make a difference. They help manufacturers build a cloud-native foundation — using platforms like Azure and AWS — with continuous integration (CI/CD), robust monitoring, and security baked in.

Because let’s face it — if your infrastructure can’t keep up, your smart factory won’t be that smart for long.

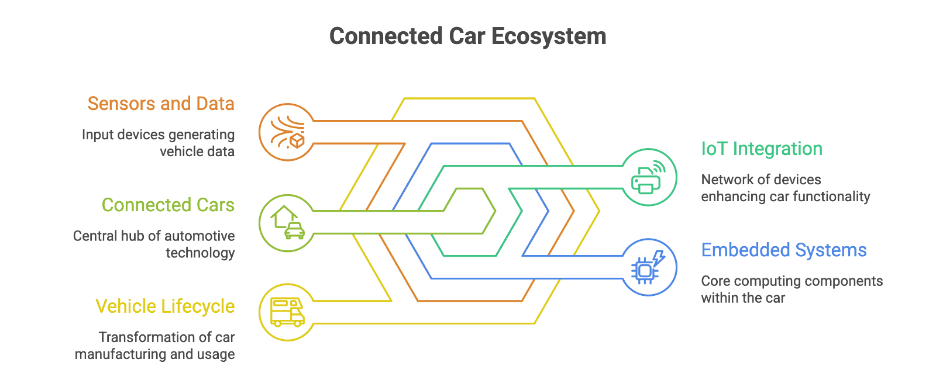

Connected Cars and IoT Integration

Let’s talk about what’s happening inside the car — and how that’s reshaping how manufacturers build them.

Modern vehicles are rolling computers, packed with embedded systems, sensors, GPS, cameras, radar, and software that all generate constant streams of data. This is the Internet of Things (IoT) in motion — and it’s revolutionizing the entire vehicle lifecycle.

Use Cases of IoT in Automotive:

- Remote diagnostics: Telematics platforms monitor engine health, emissions, tire pressure, and more — allowing for predictive maintenance and reduced downtime.

- Usage-based insurance (UBI): Driving behavior data lets insurers personalize premiums.

- Fleet management: Logistics companies track vehicle performance, fuel usage, and delivery times in real time.

Software-Defined Vehicles (SDVs)

As highlighted by Lemberg Solutions, vehicles are shifting to software-defined architectures, where most features — from entertainment to safety — are controlled via code, not hardware.

Manufacturers now need DevOps pipelines, OTA (over-the-air) update systems, and cloud backends to support this new vehicle model.

Partnering for Smart Vehicle Success

Digitalizing the vehicle doesn’t stop at design — it continues through production, maintenance, and even user experience post-sale.

With partners like Gart Solutions, automakers can build custom IoT platforms, integrate them with manufacturing systems, and ensure that both the vehicle and its digital twin operate in sync across the entire lifecycle.

Vehicle-to-Vehicle (V2V) and V2I Communication

Now let’s go a step further — what happens when cars talk to each other and to the world around them?

V2V and V2I communication technologies enable vehicles to exchange real-time data with other cars (V2V) and with traffic infrastructure (V2I), unlocking a safer and more intelligent transportation system.

Why It Matters:

- Safety: Cars alert each other about sudden braking, icy roads, or accidents ahead.

- Traffic optimization: Vehicles adjust speeds to avoid congestion in coordination with smart traffic lights.

- Autonomous driving foundation: These communication systems lay the groundwork for fully self-driving cars.

The future of transportation lies in Vehicle-to-Everything (V2X) — connecting not just cars and traffic systems, but also pedestrians, cyclists, and even the electrical grid for smarter EV charging.

But here’s the catch — V2X requires a robust backend infrastructure that supports fast data processing, low latency, and secure communication protocols. That’s exactly the kind of architecture that Gart Solutions delivers through cloud-native DevOps stacks and secure hybrid infrastructures.

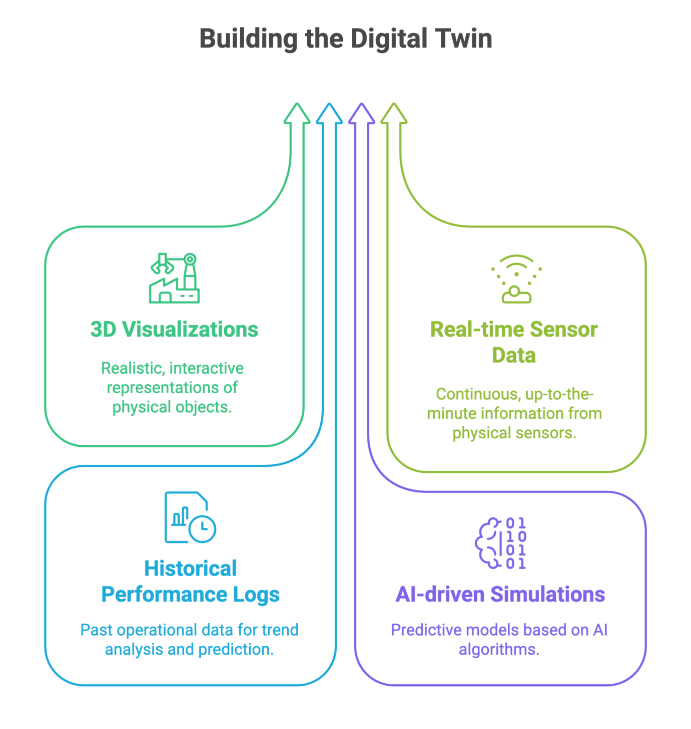

Digital Twin Technology in Automotive Production

Imagine having a virtual replica of your entire manufacturing line — one that updates in real time, lets you simulate changes, and helps your team make faster, smarter decisions. That’s the power of digital twin technology, and it’s no longer science fiction — it’s becoming standard practice in modern automotive manufacturing.

A digital twin is a live, data-powered model of a physical system — like a production line, a robot arm, or even an entire vehicle. It combines:

- 3D visualizations

- Real-time sensor data

- Historical performance logs

- AI-driven simulations

This allows manufacturers to test “what-if” scenarios without touching a single piece of hardware. Do you want to increase your throughput? Change shift patterns? Replace a machine? Do it virtually first — then bring it to life with confidence.

Real-World Example: NSG’s Digital Twin Journey

In a recent AWS Automotive & Manufacturing Meetup, NSG’s UK factory showed how they built a digital twin of their production line using AWS IoT TwinMaker. By integrating data from conditioning rooms and critical sensors, they created a real-time 3D model where engineers could:

- Walk through the virtual plant remotely

- Identify inefficiencies

- Simulate equipment upgrades

- Prevent quality issues before they occurred

The results? Over £100,000 in savings — in just a few months. This wasn’t just about tech — it was about having the right roadmap, trusted tech partners, and a team that understood how to use data daily.

How Gart Solutions Can Help

At Gart Solutions, we help manufacturers build scalable, cloud-based digital twin architectures using Azure Digital Twins, AWS TwinMaker, and custom APIs. Whether you’re starting with one line or scaling across global sites, we design the architecture, handle integration, and deliver real-time performance dashboards — all while keeping security and ROI front and center.

In fact, in one of our case studies, we leveraged Azure infrastructure to support high-demand AI processing at 81% lower cost. That same cloud-native mindset powers how we approach digital twins: fast, flexible, cost-efficient, and tailored to your needs.

The takeaway? A digital twin isn’t just a visualization — it’s a business decision tool that boosts uptime, cuts waste, and turns insight into action.

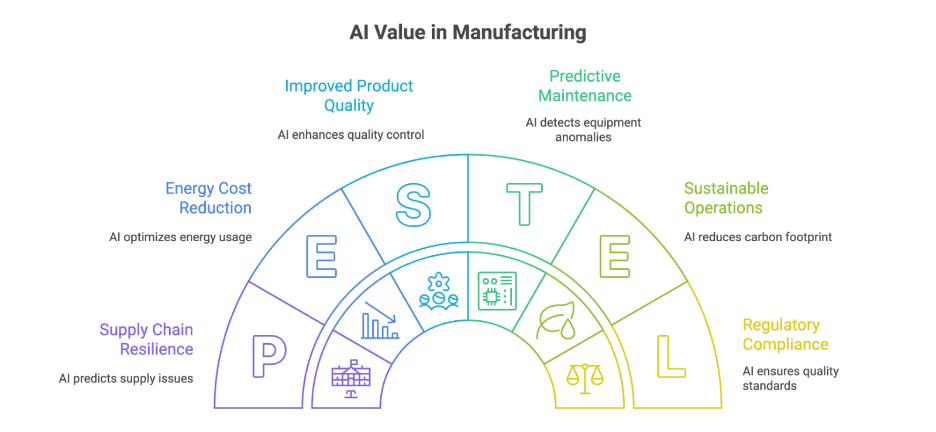

AI and Machine Learning in Automotive Factories

Let’s face it — factories generate more data than most businesses know what to do with. The difference between industry leaders and laggards? Leaders use AI to turn data into action.

Artificial Intelligence (AI) and Machine Learning (ML) are being deployed across automotive factories to automate decision-making, uncover patterns, and prevent costly mistakes.

Where AI Delivers the Most Value:

- Predictive Maintenance: AI models like Amazon Lookout for Equipment (used by NSG) detect anomalies such as sudden temperature changes, abnormal vibrations, or system lags — all before a breakdown happens.

- Quality Control: Computer vision systems scan welds, paint jobs, and assembly lines with near-perfect accuracy. No fatigue. No missed defects.

- Supply Chain Forecasting: AI predicts demand surges, delays, or raw material issues, allowing procurement to react early.

- Energy Optimization: AI tracks usage patterns and recommends equipment schedules that lower energy bills and carbon footprints.

Why DevOps and Data Infrastructure Matter

AI can’t thrive without data pipelines. That’s why Gart Solutions brings DevOps practices into manufacturing environments — ensuring that:

- Data flows securely and reliably from sensors to AI models.

- Models are trained and updated through automated CI/CD.

- Dashboards reflect real-time insights, not yesterday’s guesses.

We don’t just implement AI — we build the infrastructure, workflows, and support systems that let AI evolve with your business. Whether it’s Microsoft’s ML tools, AWS SageMaker, or open-source platforms — we tailor the solution to your reality.

Because AI in manufacturing isn’t just about cool tech — it’s about staying ahead of your next bottleneck, defect, or cost overrun. And that’s a transformation worth investing in.

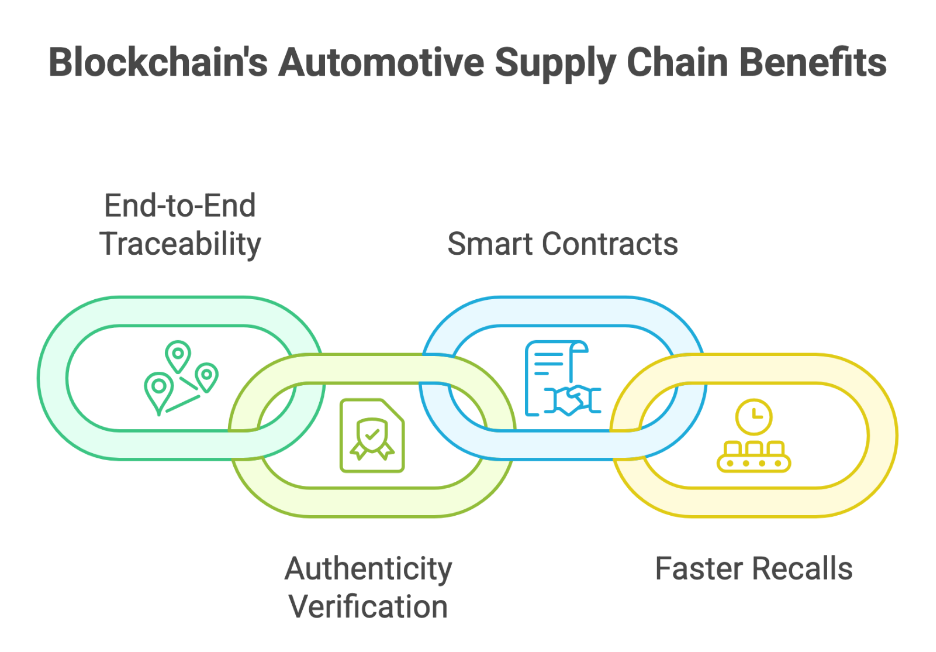

Blockchain in Supply Chain Management

Supply chains in the automotive world are notoriously complex — thousands of components, dozens of countries, multiple vendors, and endless compliance requirements. One wrong part, one mislabeled batch, and the whole operation could be at risk. That’s why blockchain is becoming a critical player in supply chain transformation.

But let’s clear something up — blockchain isn’t just for Bitcoin. In manufacturing, it acts as an immutable, transparent ledger that records every step a part takes, from sourcing raw materials to final assembly. No room for guesswork. No space for fraud.

Key Benefits of Blockchain in Automotive Supply Chains:

- End-to-End Traceability: Track every component from origin to destination.

- Authenticity Verification: Prevent counterfeit parts by validating origins and supplier certifications.

- Smart Contracts: Automate procurement processes based on predefined triggers (e.g., payment release upon part delivery).

- Faster Recalls: Isolate faulty batches instantly instead of halting entire product lines.

Real-World Application

Companies like Renault, BMW, and Ford are already using blockchain to verify the ethical sourcing of raw materials — like cobalt — and to track parts in real time. Blockchain not only makes their supply chains more ethical but also far more efficient.

How Gart Solutions Supports Blockchain Adoption

At Gart Solutions, we help manufacturing clients integrate blockchain platforms like Hyperledger, Ethereum-based chains, or even AWS Managed Blockchain into their existing infrastructure. Our approach includes:

- Designing the blockchain architecture

- Integrating smart contracts with ERP systems

- Securing on-chain/off-chain data

- Training your internal teams for operational independence

Whether you’re looking to gain transparency, ensure regulatory compliance, or just make your supply chain more resilient, blockchain — implemented the right way — can deliver all three. And with our team, you get more than just implementation; you get a long-term transformation partner who understands the unique challenges of manufacturing ecosystems.

Cloud Computing and Data Management

All this data — from sensors, software, cameras, and vehicles — needs somewhere to live, be processed, and turned into insight. That’s where cloud computing becomes the digital foundation of modern automotive manufacturing.

Gone are the days when on-prem servers could keep up with the scale and speed of smart manufacturing. Today, successful companies run their digital operations on cloud-native infrastructure — agile, scalable, and always-on.

What Cloud Brings to the Table:

- Elastic scalability: Spin up more compute power as production ramps up.

- Global access: Engineers, vendors, and stakeholders collaborate from anywhere.

- Data lakes: Store structured and unstructured data for deeper analysis.

- Security and compliance: Encrypted data storage, access control, and disaster recovery baked in.

Platforms like AWS, Azure, and Google Cloud offer powerful services tailored for industrial applications — from IoT integration to AI pipelines to digital twin modeling.

Gart Solutions – Your Transformation Partner: Case Studies

Our team at Gart Solutions specializes in building cloud-first infrastructures for manufacturers.

In fact, in our case study with an AI-based quality inspection platform, we helped cut cloud compute costs by 81% using Azure Spot VMs — proving that the cloud isn’t just powerful, it’s cost-effective when done right. Another case was revolutionizing Autonomous Vehicle Operations with Blockchain DevOps Services.

From CI/CD pipelines to hybrid-cloud environments, from edge compute to full migration — we tailor your cloud journey based on where you are and where you need to go.

And we do more than deploy. We maintain, optimize, and secure your cloud infrastructure so you can focus on building vehicles — not fighting server issues.

AR/VR and Immersive Technologies

If digital transformation had a “cool” factor, this would be it. Augmented Reality (AR) and Virtual Reality (VR) are transforming everything from training to design in the automotive industry — and the ROI is far more than skin deep.

Real-World Use Cases:

- Worker Training: Instead of manuals and classroom sessions, workers use VR headsets to experience fully interactive training environments — reducing onboarding time and improving retention.

- Remote Collaboration: Engineers from different countries can meet inside a virtual car model, review designs, and annotate changes in real time.

- Assembly Guidance: AR overlays can guide workers on the shop floor, showing step-by-step instructions or flagging potential errors visually.

- Customer Experience: Showrooms use VR to let customers customize and “drive” vehicles in a virtual environment before making a purchase.

OEMs like Ford, Audi, and BMW are already deploying these tools to accelerate R&D cycles and reduce prototyping costs.

The Backend That Makes It Possible

Here’s what most companies overlook: AR/VR isn’t just about headsets. It requires a powerful data backend — one that can deliver high-resolution models, sync with digital twins, and support collaboration tools. That’s where cloud-native architecture and DevOps practices come into play.

With Gart Solutions, you get both — the immersive tech and the infrastructure that powers it. We ensure your AR/VR strategy is:

- Fully integrated with your production systems

- Secure, fast, and reliable

- Scalable across locations and teams

Because immersive tech isn’t the future — it’s happening right now. And it’s already giving forward-thinking manufacturers a serious edge.

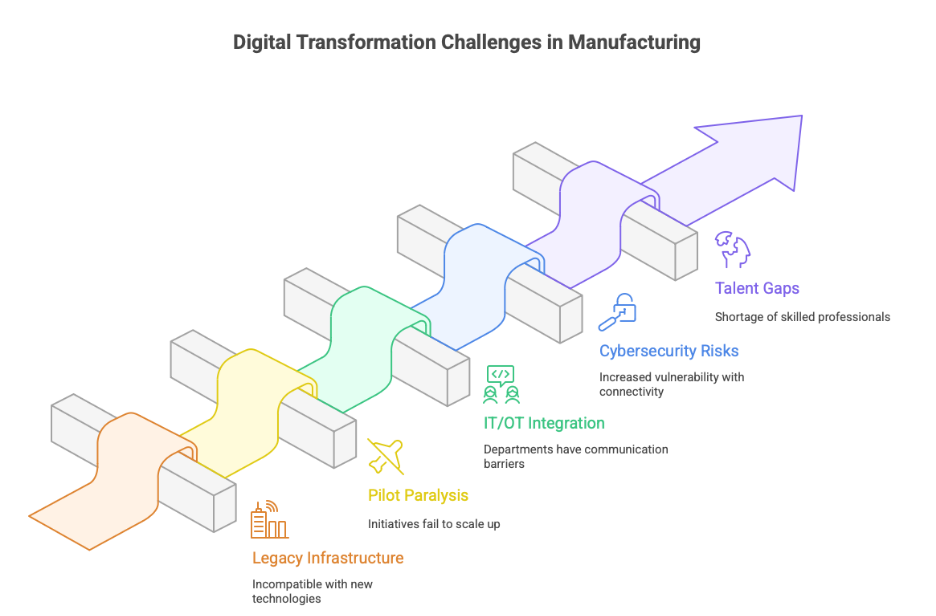

Overcoming Challenges in Digital Transformation

Let’s not sugarcoat it — digital transformation in manufacturing is hard. It’s not just a matter of buying new software or upgrading machines. You’re changing how people work, how data flows, and how decisions are made. And most importantly, you’re navigating a delicate balance between legacy systems and cutting-edge technology.

The Big Challenges

- Legacy Infrastructure — old PLCs, SCADA systems, and on-prem ERP tools were never designed to work with cloud, AI, or IoT. Bridging this tech gap is one of the first hurdles.

- Pilot Paralysis — qas McKinsey reports, 70% of manufacturers get stuck in pilot mode, unable to scale initiatives beyond small test cases.

- Lack of IT/OT Integration — operations teams (OT) and IT departments often speak different languages. This cultural divide can stall even the best-intentioned projects.

- Cybersecurity Risks — more connectivity means more vulnerability. Without proper DevSecOps practices, digital expansion can become a liability.

- Talent Gaps — skilled professionals who understand both manufacturing and digital systems are in short supply — and high demand.

The Human Factor

Digital transformation is as much about people as it is about platforms. If your plant workers don’t trust or understand the new tools, they won’t use them. That’s why training, change management, and user-focused design are critical.

At Gart Solutions, we put people at the center of every project. Our approach includes:

- Conducting IT/OT alignment workshops

- Delivering on-site and remote training programs

- Building dashboards and UIs that match how your teams already work

- Creating phased rollouts so teams aren’t overwhelmed

We’ve learned that success comes when transformation is gradual, strategic, and deeply aligned with business goals. And that means having a partner who knows when to push forward — and when to pause, listen, and support.

From POCs to Scalable Transformation

It’s one thing to build a cool pilot. It’s another thing entirely to scale it across multiple lines, plants, or even countries. But that’s where true ROI lies.

The problem? Many manufacturers stall after an initial proof of concept (POC). The use case works great in isolation — but when it’s time to expand, things break down: systems don’t integrate, the infrastructure can’t handle the load, and leadership loses patience.

What It Takes to Scale

- A Clear Roadmap — what does the full rollout look like? What systems are impacted? What teams need to be trained?

- A Modular Architecture — your systems need to be flexible enough to scale horizontally (more locations) and vertically (more functionality).

- KPI Alignment — you must be able to measure and prove value at every stage.

- Partner Collaboration — scaling digital systems means more moving parts — cloud vendors, OEMs, tech partners. You need someone who can orchestrate the whole stack.

Lessons from NSG and Gart Solutions

Take NSG’s work with AWS — by combining a clear data story with IoT dashboards and a digital twin, they built a scalable model that delivered £100,000+ in savings in months.

Now contrast that with Gart’s Azure case study, where cloud optimization cut AI infrastructure costs by 81% — not just at the pilot level, but across ongoing production. That’s real scalability. That’s transformation with traction.

When you work with Gart Solutions, you’re not just getting a POC partner — you’re getting a strategic consultant, cloud architect, and long-term advisor who’s already helped clients scale digital operations successfully.

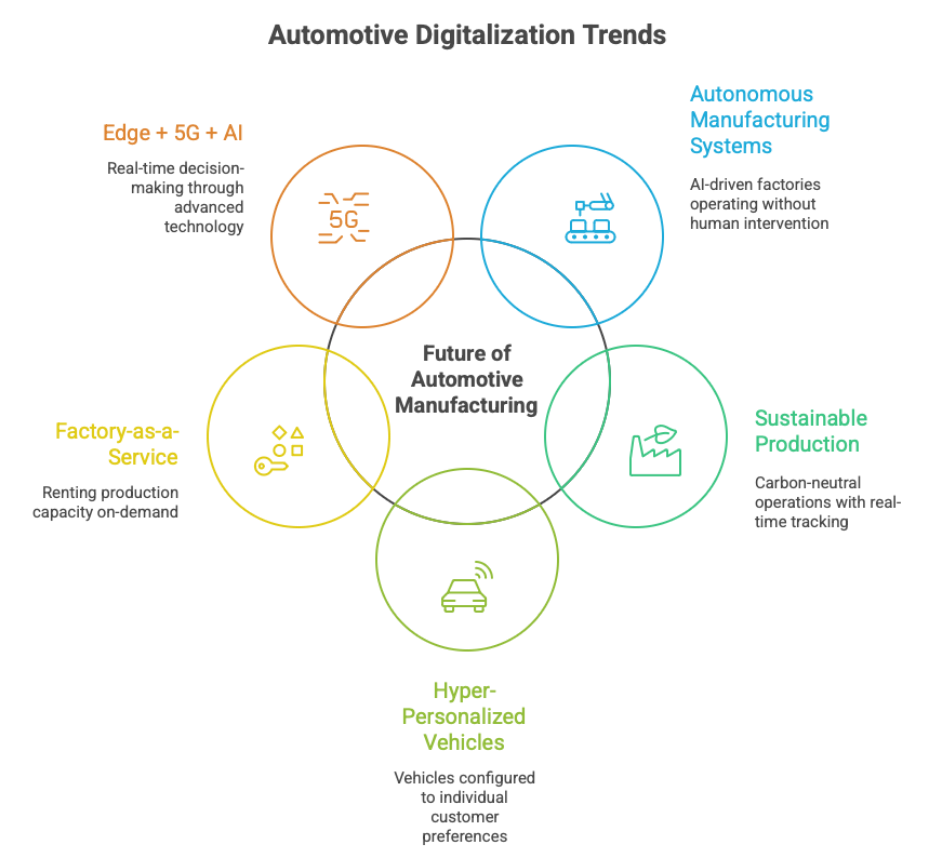

Future Trends in Automotive Digitalization

If you think we’ve already hit “peak digital,” think again. The future of automotive manufacturing is even more connected, intelligent, and autonomous. Here’s what’s coming — and how to get ready for it.

1. Autonomous Manufacturing Systems

Picture this: AI models managing entire production shifts — adjusting workflows, rerouting tasks, and optimizing output without human intervention. That’s the promise of self-healing and self-learning factories. Cloud-native infrastructure and advanced ML will be the foundation.

2. Sustainable, Net-Zero Production

Governments and consumers are pushing hard for carbon-neutral operations. Manufacturers will need real-time carbon tracking, smart energy grids, and digital tools to monitor every watt and emission. Blockchain and IoT will be critical here.

3. Hyper-Personalized Vehicles

Forget “standard models.” Future vehicles will be configuredhe software level per customer — infotainment systems, performance settings, even interior lighting. All powered by cloud, edge computing, and SDV platforms.

4. Factory-as-a-Service Models

Why build your own factory when you can rent production capacity on-demand? Think of it like AWS for manufacturing. Digitally enabled contract manufacturing is already emerging, and it will change how OEMs scale.

5. Edge + 5G + AI = Instant Insight

The trifecta of edge computing, 5G connectivity, and real-time AI models will allow factories to make decisions in microseconds — enabling machine-to-machine orchestration on an entirely new level.

With these trends on the horizon, having a flexible, future-proof IT foundation is no longer optional. It’s the minimum entry requirement. And that’s what Gart Solutions delivers — not just a transformation for today, but a roadmap for tomorrow.

Conclusion

Digital transformation in automotive manufacturing isn’t a destination — it’s a journey. One that requires vision, grit, and the right partners by your side.

Whether it’s integrating AI for predictive maintenance, building digital twins, or optimizing cloud infrastructure to cut costs, manufacturers that embrace digital now will dominate the future. Those that wait? Risk falling behind in an industry that’s moving faster than ever.

As we’ve seen through real-world examples — from NSG’s factory modernization to Gart’s cost-saving Azure solutions — digital transformation is achievable, measurable, and scalable. But only with the right strategy.

If you’re ready to reduce downtime, boost efficiency, and build a factory fit for the future — Gart Solutions is here to help you make that leap.